- Equipment

- Parts

- Automation

- Applications

- Industries

- Services

- Our Company

- Portal Login

- Webinars

- Test Center

- Videos

- Downloads

- LanguagesEnglishEspanolPortuguês

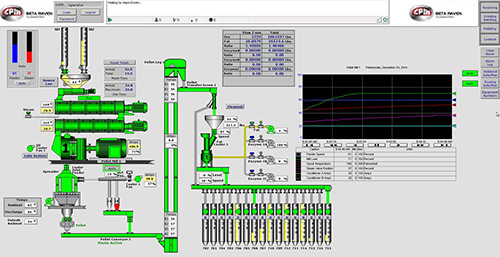

MM4 Pelleting automation efficiently controls your pellet mill to maximize productivity and prevent downtime.

This screenshot shows the product being transferred to the proper pellet mill and then to its assigned destination. It also shows key information such as mash temperature, tons per hour and cooler performance. MM4 Pelleting can be set up for your specific requirements and equipment, with labeling and color-coding that easily conveys the information you need.

At CPM Automation Group, we take pride in providing the very best customer service. Our service technicians are available 24 hours a day, 7 days a week. With remote service access, our technicians are able to connect to your system to find and correct any performance issues, eliminating costly service trips. We offer a variety of service plans to meet your operational needs.