- Equipment

- Parts

- Automation

- Applications

- Industries

- Services

- Our Company

- Portal Login

- Webinars

- Test Center

- Videos

- Downloads

- LanguagesEnglishEspanolPortuguês

Extruder-Compounding Process Control systems employ the latest technology and are designed to meet the demanding requirements of operating 24 hours a day, 365 days a year.

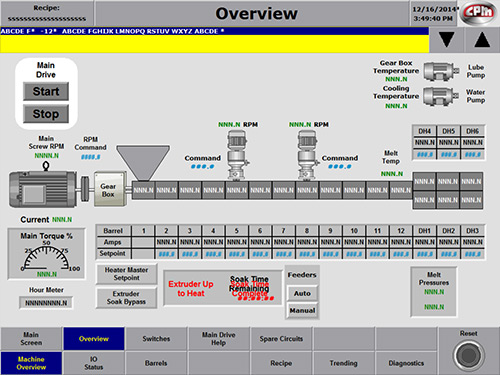

This screenshot shows the interface of the extruder-compounding automation process. It also shows critical information such as speed, torque and temperature. The system can be set up for your specific requirements and equipment, with labeling and color-coding that easily conveys the information you need.

At CPM Automation Group, we take pride in providing the very best customer service. Our service technicians are available 24 hours a day, 7 days a week. With remote service access, our technicians are able to connect to your system to find and correct any performance issues, eliminating costly service trips. We offer a variety of service plans to meet your operational needs.